ABOUT US

CHALLENGING THE GLOVE INDUSTRY TO DO BETTER

Headquartered in beautiful British Columbia, 11 Crossings™ develops quality medical and industrial consumables that combine affordability with environmental and social sustainability. The Company’s core mission is to decrease the costs of consumable supplies by helping commercial industries and community health organizations build supply chain resiliency, improve access to innovative manufacturers, and diversity away from large, profit-focused corporations

11 Crossings started as a response to a problem in the market. During the Covid-19 pandemic, it became clear that single-use nitrile gloves are an important first line of defense against the spread of pathogens. However, the sudden ramp up in global production of these products brought to light serious environmental and societal issues that had not attracted mainstream attention prior to the pandemic. From the massive carbon footprint created by the largest glove manufacturers that burn coal to fuel production, to shocking revelations of human rights violations in factories making gloves for trusted global brands, it became clear that the nitrile glove industry was contributing to serious environmental and societal problems. It was at this moment that we asked ourselves 2 key questions:

- Does ensuring the protection of workers, customers, and patients have to come at such a steep ethical and environmental cost?

- Can we improve the environmental and societal profile of glove production and distribution without reducing the affordability and quality of the finished product?

Like any business seeking to disrupt an industry, we set out to do our due diligence. After multiple trips, factory audits, technical evaluations, and financial calculations, a path to success started to emerge. In 2023, with the support of progressive glove manufacturers that are industry leaders in improving environmental and social sustainability, we launched a new nitrile glove supply chain model called: “ESG Vendor-Direct”. Through this model, Health Care Organizations are now able to access factory-direct pricing that is benchmarked against objective, verifiable indexes such as the price of raw acrylonitrile, shipping costs, and foreign exchange. Unlike traditional distribution models where glove distributors maximize profits when market conditions improve, our ESG Vendor-Direct model directly passes savings to the participating Health Care Organization in real time. The result is a true partnership, where both parties work together to create price efficiencies and positive social and environmental impacts, regardless of market fluctuations.

As an innovative business that is challenging the way large corporations have profited from the disposable glove industry, we sincerely thank all of our supporters and valued customers for giving us the ability to follow our passion. Our journey has just started, and we look forward to using technology, innovation, and a unwavering commitment to social and environmental sustainability to improve health care outcomes across North America!

SAFEGUARDING HUMAN RIGHTS IN THE GLOVE SUPPLY CHAIN

As part of our commitment to deliver the highest standards of social and environmental sustainability across our entire supply chain, we are constantly seeking to do better. Talking about sustainability is important, but being able to measure and independently prove a positive impact is the ultimate satisfaction. When you purchase Forteflex™ MAESTRO™, ON-CALL™ and RECHARGE™ nitrile gloves, you are supporting manufacturers that are registered members of the AMFORI Business Social Compliance Initiative (BSCI).

The AMFORI BSCI Code of Conduct Is a commitment document for AMFORI members and their business partners to exercise human rights due diligence and environmental protection in their global supply chains in line with Internationally recognized principles (e.g., International Labour Organization, Organisation for Economic Co-operation and Development, United Nations Guiding Principles on Business and Human Rights). In evaluating a BSCI score, AMFORI looks at 13 “Social Performance Areas”, including:

11 Crossings™ Is Proud To Work With Vendors That Have Been Awarded The Highest " A " Rating Across All 13 Social Performance Areas Of The BSCI Framework.

1. Social management system and cascade effect

2. Workers involvement and protection

3. The right of freedom of association and collective bargaining

4. No discrimination, violence, or harassment

5. Fair remuneration

6. Decent working hours

7. Occupational health and safety

8. No child labour

9. Special protection for young workers

10. No precarious employment

11. No bonded, forced labor or human trafficking

12. Protection of the environment

13. Ethical business behaviour

SAFEGUARDING HUMAN RIGHTS IN THE GLOVE SUPPLY CHAIN

As part of our commitment to deliver the highest standards of social and environmental sustainability across our entire supply chain, we are constantly seeking to do better. Talking about sustainability is important, but being able to measure and independently prove a positive impact is the ultimate satisfaction. When you purchase Forteflex™ MAESTRO™, ON-CALL™ and RECHARGE™ nitrile gloves, you are supporting manufacturers that are registered members of the AMFORI Business Social Compliance Initiative (BSCI).

The AMFORI BSCI Code of Conduct Is a commitment document for AMFORI members and their business partners to exercise human rights due diligence and environmental protection in their global supply chains in line with Internationally recognized principles (e.g., International Labour Organization, Organisation for Economic Co-operation and Development, United Nations Guiding Principles on Business and Human Rights). In evaluating a BSCI score, AMFORI looks at 13 “Social Performance Areas”, including:

1. Social management system and cascade effect

2. Workers involvement and protection

3. The right of freedom of association and collective bargaining

4. No discrimination, violence, or harassment

5. Fair remuneration

6. Decent working hours

7. Occupational health and safety

8. No child labour

9. Special protection for young workers

10. No precarious employment

11. No bonded, forced labor or human trafficking

12. Protection of the environment

13. Ethical business behaviour

11 Crossings™ Is Proud To Work With Vendors That Have Been Awarded The Highest " A " Rating Across All 13 Social Performance Areas Of The BSCI Framework.

IMPROVING THE ENVIRONMENTAL IMPACT OF GLOVE PRODUCTION

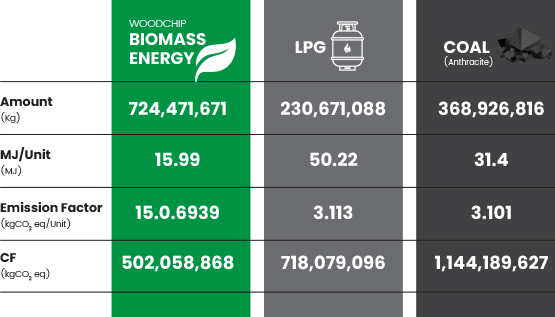

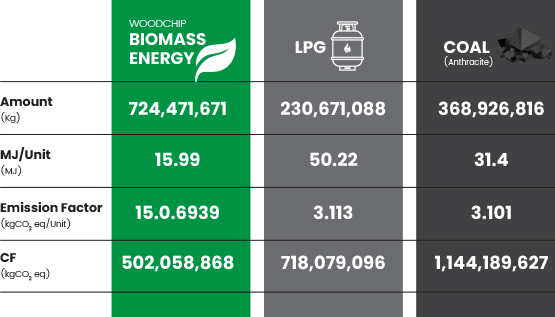

The inconvenient truth is that traditional manufacturing processes for nitrile gloves continue to generate significantly negative environmental outcomes. To this day, many of the largest nitrile gloves manufacturers globally still rely on the combustion of coal to fuel their operations. However, there are reasons to be optimistic about the future. Several manufacturers have made major investments in transitioning to sustainable energy sources, demonstrating that a greener future path is possible.

In line with our commitment to improve the environmental profile of the nitrile glove industry, our MAESTRO™, ON-CALL™ and RECHARGE™ nitrile gloves are produced utilizing thermal energy generated from 100% renewable woodchip biomass. As summarized in the table above, renewable woodchip biomass energy generates almost 30% less carbon emissions than burning liquified natural petroleum (“LNP”), and 57% less carbon emissions than burning coal. But the advantages don’t stop there. Forteflex™ MAESTRO™, ON-CALL™ and RECHARGE™ nitrile glove manufacturing lines are part of a larger sustainable production cycle that utilizes rubber trees that have reached the end of their latex producing lifecycle. These trees are harvested to generate woodchip feedstock, and a new tree is planted in its place. These production lines also recycle up to 25% of the water used in glove production and have developed sustainable packaging that is made from 80% recycled materials. As we continue on our mission to improve the environmental footprint of the glove industry, your choice to support Il Crossings helps us make a real contribution to reducing harmful environmental impacts. Thank you for your support!

IMPROVING THE ENVIRONMENTAL IMPACT OF GLOVE PRODUCTION

The inconvenient truth is that traditional manufacturing processes for nitrile gloves continue to generate significantly negative environmental outcomes. To this day, many of the largest nitrile gloves manufacturers globally still rely on the combustion of coal to fuel their operations. However, there are reasons to be optimistic about the future. Several manufacturers have made major investments in transitioning to sustainable energy sources, demonstrating that a greener future path is possible.

In line with our commitment to improve the environmental profile of the nitrile glove industry, our MAESTRO™, ON-CALL™ and RECHARGE™ nitrile gloves are produced utilizing thermal energy generated from 100% renewable woodchip biomass. As summarized in the table above, renewable woodchip biomass energy generates almost 30% less carbon emissions than burning liquified natural petroleum (“LNP”), and 57% less carbon emissions than burning coal. But the advantages don’t stop there. Forteflex™ MAESTRO™, ON-CALL™ and RECHARGE™ nitrile glove manufacturing lines are part of a larger sustainable production cycle that utilizes rubber trees that have reached the end of their latex producing lifecycle. These trees are harvested to generate woodchip feedstock, and a new tree is planted in its place. These production lines also recycle up to 25% of the water used in glove production and have developed sustainable packaging that is made from 80% recycled materials. As we continue on our mission to improve the environmental footprint of the glove industry, your choice to support Il Crossings helps us make a real contribution to reducing harmful environmental impacts. Thank you for your support!

In line with our commitment to improve the environmental profile of the nitrile glove industry, our MAESTRO™, ON-CALL™ and RECHARGE™ nitrile gloves are produced utilizing thermal energy generated from 100% renewable woodchip biomass. As summarized in the table above, renewable woodchip biomass energy generates almost 30% less carbon emissions than burning liquified natural petroleum (“LNP”), and 57% less carbon emissions than burning coal. But the advantages don’t stop there. Forteflex™ MAESTRO™, ON-CALL™ and RECHARGE™ nitrile glove manufacturing lines are part of a larger sustainable production cycle that utilizes rubber trees that have reached the end of their latex producing lifecycle. These trees are harvested to generate woodchip feedstock, and a new tree is planted in its place. These production lines also recycle up to 25% of the water used in glove production and have developed sustainable packaging that is made from 80% recycled materials. As we continue on our mission to improve the environmental footprint of the glove industry, your choice to support Il Crossings helps us make a real contribution to reducing harmful environmental impacts. Thank you for your support!

CHALLENGING THE GLOVE INDUSTRY TO DO BETTER

If you have a passion for environmental sustainability and ethical business practices, and are looking for affordable gloves that feel and perform great, we would love to hear from you!

We are a 100% remote work organization and so check back often to learn about flexible opportunities to help us make a positive impact. In order to deliver some of the most cost effective pricing in the industry while staying true to our commitments to environmental sustainability and ethical supply chains, we keep our overhead expenses to a minimum. As a result, we rely almost entirely on positive reviews, and our wholesale distribution partners to reach new audiences and markets. If you would like to support us by making a purchase, or leaving us a kind note of encouragement or positive review on Google, it would mean the world to us!

WE WOULD LOVE TO HEAR FROM YOU!

CONTACT 11 CROSSINGS™ FOR PRICING AND PRODUCT INFORMATION